Services for Turnkey Projects

FCA Turnkey Projects is totally committed to provide Quality. From Revamping the existing manufacturing plant, expansion of the existing manufacturing plant to Building a new manufacturing Plant set up we have provided the higher quality of work and we have mastered it all.

Have a look at our services:

- Architectural& Structural

- Plant process Equipments

- Modular Clean Room

- HVAC

- Electricals

- Mechanical & utilities

With the assistance of an experienced and technical team, we are able to undertake an assortment of turnkey projects of biscuits /cracker/ cookies manufacturing. Our team of experienced designers, engineers and other associated staff allow us to successfully give solutions to the extent of:

- Selection of location and lay-out.

- Preparation of Engineering Drawings in consent with the client.

- Selection and supply of Plant & machinery and utilities.

- Training of skilled staff.

- Product mix selection and operational consultancy.

- Certification of food safety norms and standards.

Feasibility Studies

FCA Turnkey can provide its customers with a complete feasibility study comprising of:

- Market Study

- Technical Study

- Financial Study

The studies conducted will rely on both primary and secondary data, which will involves both desk and field works. Accordingly, the typical approach employed for such studies includes followings:

- Key Project Goals

- Personnel Requirement

- Licensing and Regulatory Requirements

- Production Capacity

- Production Budget

- Total Investment Cost

- Annual Income Forecast

- Annual Cost of Production

- Net Surplus

- Business Valuation

- Income Statement

The Detailed Feasibility Report will help you to arrive at a well thought, techno commercial decision to proceed with most viable project plan.

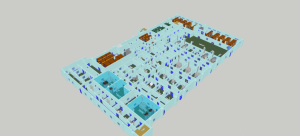

Master Planning

A Master Plan, also called a comprehensive plan, provides a long-term vision for the built environment of a Food and Cosmetic Factories. It guides the appropriate use of lands in order to Plan and envisage future growth potential. As a result, the Master Plan has a direct relationship to the growth of organization.

FCA Turnkey has an Expert team of Architects and Designers to Make Futuristic Master Plan to identify:

- Suitable locations for Manufacturing, Administration Research & Development and Utilities.

- Green Belt and Environment management.

- Opportunities to extend and/or improve open space, recreational areas, and civic facilities

- Strategies for Future development

Why should a Master Plan be important to you?

The simple answer is that a Master Plan is important because it affects Future growth plan.

- Master Plan helps to adopt new manufacturing technologies.

- Food & Cosmetic Manufacturing is very dynamic and the master plan helps you to device compliance with future GMP Standards.

- Master plan helps you to adopt new automation.

Concept Engineering

Concept Engineering will have following stages:

Stages1:

This involves gathering functional requirements of the proposed facility which includes production process together with the required level of automation

- Product forms

- Batch sizes

- Measures to avoid cross contamination.

- Type of equipment and machinery

- Inventory norms

- Expansion philosophy

Stages2:

Starts by addressing the following concerns:

- Preliminary layout based on availability of space and resources

- Targeted environmental cleanliness category

- Optimal water quality and water treatment facilities

Stages3:

All the above data are finally used to prepare the following:

All the above data are finally used to prepare the following:

An overall budget for project execution The entire facility layout for the preliminary stage as per national and international regulatory norms

- Conceptualization of building construction

- Drawing out user requirement specification (URS)

- Drawing out project schedules through bar charts

- Water generation and distribution system design

- Production environment designing like heating, ventilation and air conditioning

Basic Engineering and Detailed Engineering

During BASIC ENGINEERING, the following definitions of the Project will be developed:

- Alternative Plant Layouts meeting International regulations and GMP requirements

- Man/material flow drawings on the approved layout

- Design of Heating, Ventilation, Air Conditioning and Pressure Differential system with proposed Air Flow Diagram

- Design on treatment, purification, filtration and distribution of various utility systems like Water, Steam, and Compressed Air etc.

- Estimate requirements of various utilities

- Develop P&IDs for Process and Utilities

- Estimate Electric Power requirements for the plant and suggest High Tension and Low Tension Distribution schemes

Detailed Engineering

- Process Engineering including selection of the right equipment

- Electrical Engineering

- HVAC

- Instrumentation

- Building Management and Automation Systems

- Preparation of detailed specifications, data sheets and Bill of Quantities for various plants, equipment, machinery and system

- Supply of various plant equipment, machinery and systems

Activities involved in Detailed Engineering

Civil Layouts

- Plot Layout

- Area Layout

- Man / Material Movement…etc.

Drainage Layouts

- Industrial Drainage

- Domestic Drainage …etc.

- Soil Drainage …etc.

Lighting

- Illumination Design

- Lighting Layout …etc.

HVAC (Heating Ventilation and Air Conditioning)

- HVAC Design

- Air Handling Unit (AHU) Locations

- Air Flow Diagrams

- Ducting Layouts

- BOQ…etc.

Schematic Pipeline

- Purified Water Generation System

- Water for Injection (WFI)

- Compressed Air

- Pure Steam

- Plant Steam

Project Management

Project management in our field of operations consists of the application of knowledge, abilities, tools and techniques enable us to complete project activities in order to satisfy customer requirements and thus accomplish the final goal with efficacy and efficiency.

The Project management functions include:

- Project Structure

- Project Scheduling and Monitoring

- Propose cost and safety measures during detailed engineering

- Technical assistance in getting statutory approvals

- Checking availability of design information

- Detailed Project Review

- Propose cost and safety measures during detailed engineering

- Conduct periodic co-ordination meetings with Client to review actual progress of work as against planned work schedule and remove bottlenecks

- Carrying out mechanical installations, commissioning and validation

Our Project Management team is geared up to monitor every individual project with following key areas:

- Project Scope Management

- Project Integration Management

- Project Time Management

- Project Communication Management

- Project Risk Management

- Project Procurement Management.

- Project Human Resources Management.

- Project Cost Management.

- Project Quality Management

Commissioning Validation

Commissioning Validation includes the following:

- Generation of User requirement sheets.

- Design Qualification

- FAT ( Factory Acceptance Test)

- Installation Qualification

- SAT ( Site Acceptance Test)

- Operation Qualification

- Performance Qualification.

- VMP ( Validation Master Plan)

- SMF ( Site Master file )

- GMP Auditing and Gap Analysis.

- Protocol Development & execution

- Standard Operating Procedures ( SOP )

Regulatory Compliance Support

Advisory Services

- cGMP (current Good Manufacturing Practice) compliance

- Advisory services to queries pertaining to US FDA, HACCP, INDIAN FOOD INDUSTRY STANDARDS, SQF, GMP

- regulatory affairs

- Compliance audits as per current and updated statutory Food & Cosmetics regulations

- GAP Analysis/Due diligence

- Schedule ‘M’ Requirements & documentation for compliance to Indian FDA’s norms

Technical Assistance

- Site Master file as per GMP & Local FDA requirement

- Quantitative Risk Assessment ( QRA)

- Environment Impact Assessment ( EIA)

- Safety Audits.

- Energy Audits

Technical Training

- GMP and Compliance.

- GMP Auditor Training for Quality Systems.

- GMP requirement for Food, Cosmetics facilities.

- GMP requirements for the Warehouse, Utilities & Quality control.

- Food & Cosmetics Documentation for compliance with GMP

- Writing effective SOPs in a GMP Environment.

- Food &Cosmetics Manufacturing Support.

- How to conduct Internal Audits

- How to conduct on the Job Trainings.

- Training of Trainers.

- Evaluation of supervisory staff and managers after training.

- Standard Operating Procedures – QA/QC/Manufacturing/Maintenance

- On the job Training for QA/QC/Shop floor employees

- Process Validation

- Installation Qualification

- Operational Qualification Method Validation

- Facility Qualification

- Upgrading the GMP standards of the existing plant, without much of additional investment.

- Purified Water validation

- Current Good Manufacturing Practices

- Transferring Skill on Validation

- Clean Room Operations, Equipment Handling and Documentation Activities

- Personal Behavior in Clean areas

- Calibration Procedures and Maintaining Records

- WHO guidelines

- COST Improvement Projects

- Technology Transfer

- Training modules as per the customer specific requirements ….in GMP Audits, Validations and many more topics….

Get in Touch with Us